TM 9-2320-363-34-2

W A R N I N G

Adhesives, solvents, and sealing compounds can burn easily, can give off

harmful vapors, and are harmful to skin and clothing. To avoid injury or

death, keep away from open fire and use in well-ventilated area. If

adhesive, solvent, or sealing compound gets on skin or clothing, wash

immediately with soap and water.

To prevent injury, compressed air will not exceed 30 psi (207 kPa). Use

only with effective chip guarding and personal protective equipment,

goggles, shield, and gloves.

1.

CLEAN CYLINDER COMPONENTS WITH SOLVENT AND DRY WITH COMPRESSED AIR. BLOW

COMPRESSED AIR THRU OIL PASSAGE IN CONNECTING ROD TO MAKE SURE IT IS CLEAR OF

OBSTRUCTION. USE CROCUS CLOTH, WET WITH SOLVENT, TO REMOVE ANY TRACE OF

FRETTING AND/OR CORROSION ON CONNECTING ROD SADDLE AT PISTON PIN CONTACT

SURFACE BEFORE ASSEMBLY.

2.

CLEAN CYLINDER LINERS WITH SOLVENT AND DRY WITH COMPRESSED AIR.

1.

EXAMINE PISTON SKIRT AND DOME FOR SCORE MARKS, CRACKS, DAMAGED RING GROOVE

LANDS, OR INDICATIONS OF OVERHEATING. REPLACE ANY PISTON IF ANY OF THESE

CONDITIONS ARE PRESENT.

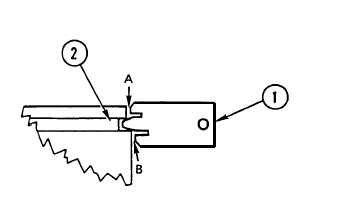

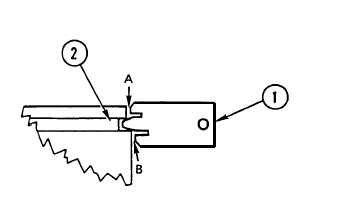

2.

USING PISTON TOP RING GROOVE GAGE (1), CHECK TAPERED FIRE (TOP) COMPRESSION

RING GROOVE (2) IN PISTON DOME. IF SHOULDER A OR B OF GAGE (1) CONTACTS PISTON

DOME, DISCARD DOME.

3.

INSERT CENTER TANG OF PISTON TOP RING GROOVE GAGE INTO FIRE COMPRESSION RING

GROOVE (2). HOLD GAGE (1) AT 90-DEGREE ANGLE TO FIRE COMPRESSION RING GROOVE

(2) WITH CENTER TANG OF GAGE (1) IN RING GROOVE (2) AS FAR AS IT WILL GO TO

PREVENT FALSE READINGS. THERE SHOULD BE NO CONTACT OF PISTON BY SHOULDERS OF

GAGE (1). IF GAGE (1) MAKES CONTACT AT POINT A OR POINT B, FIRE COMPRESSION RING

GROOVE (2) IS WORN BEYOND USABLE LIMITS AND PISTON DOME MUST BE DISCARDED.

4.

CHECK FIRE COMPRESSION RING GROOVE (2) CLEARANCE AT FOUR LOCATIONS AT

90-DEGREE INTERVALS. MEASURE RING LAND PARALLEL TO, AND AT 90 DEGREES TO, WRIST

PIN.

12-149