TM 9-2320-363-34-2

ADJUSTABLE IDLER GEAR REPLACEMENT (CONT)

7.

8.

9.

10.

11.

12.

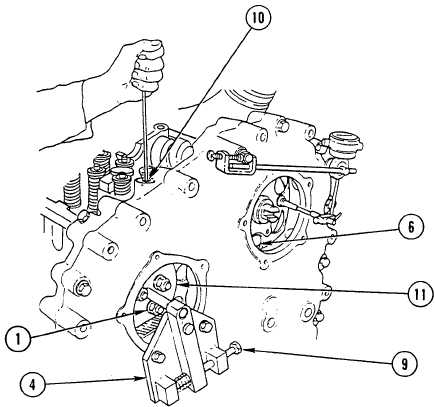

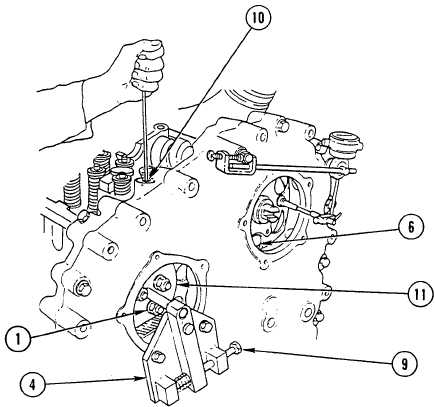

TURN ADJUSTING SCREW (9) CLOCKWISE TO MOVE ADJUSTABLE IDLER GEAR TOWARD

CAMSHAFT DRIVE GEAR (6) UNTIL THERE IS ZERO LASH.

INSERT SCREWDRIVER THRU ACCESS BOLT HOLE (10) AND ENGAGE ADJUSTABLE IDLER

GEAR TOOTH (11) TO DETERMINE GEAR LASH.

APPLY PRESSURE ON SCREWDRIVER TO HOLD ADJUSTABLE IDLER GEAR IN

COUNTERCLOCKWISE DIRECTION AND ATTEMPT TO MOVE CAMSHAFT DRIVE GEAR (6) BY

. ,

HAND.

Gear

lash.

met.

WHEN

WATCH DIAL INDICATOR POINTER. IF THERE IS ZERO LASH, POINTER WILL NOT MOVE.

NOTE

lash reading obtained on cam/idler lash pedestal is one-half actual gear

Reading on dial indicator must be doubled to determine if specification is

ZERO LASH IS OBTAINED, TURN ADJUSTING SCREW (9) APPROXIMATELY 1-1/2 TURNS

COUNTERCLOCKWISE OR UNTIL CORRECT GEAR LASH IS OBTAINED.

BAR ENGINE TO CHECK ADJUSTABLE IDLER GEAR LASH ON CAMSHAFT DRIVE GEAR (6) AT

3, 6, 9, AND 12 O’CLOCK POSITIONS.

WHEN GEAR LASH IS 0.002-0.007 IN. (0.051-0.178 mm) AT ALL FOUR POSITIONS, TiGHTEN TWO

TOP NUTS (1) TO 42-49 LB-FT (57-67 N.m).

12-104