TM 9-2320-363-34-2

8.

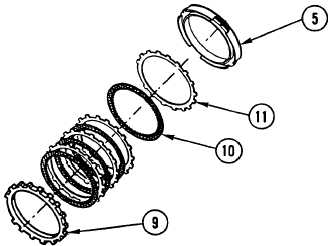

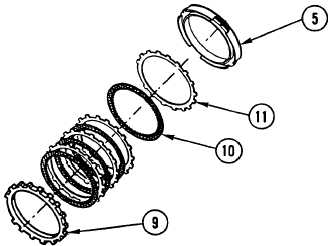

PLACE BACKING PLATE (9) ON FLAT SURFACE OF PRESS.

9.

STACK EIGHT CLUTCH PLATES (10 AND 11) ON BACKING PLATE (9) STARTING WITH FRICTION

PLATE (10) AND ALTERNATING WITH STEEL PLATE (11).

10. PLACE THIRD CLUTCH PISTON (5) ON TOP OF CLUTCH PLATES (10 AND 11).

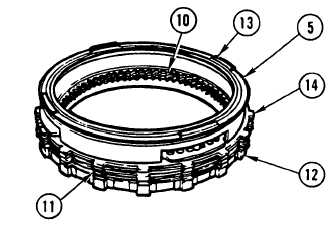

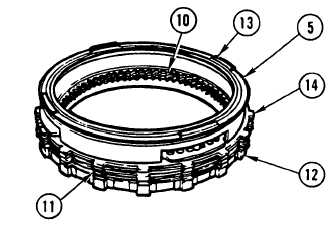

11. PRESS EVENLY ON THIRD CLUTCH PISTON (5) WITH 100 PSI (689.5 kPa).

12. MEASURE DISTANCE FROM BASE OF CLUTCH PACK (12) TO THRUST PAD (13).

13. CLUTCH PACK THICKNESS MUST BE 3.010-3.042 IN. (76.45-77.26 mm). REPLACE CLUTCH

PLATE(S) (10 AND 11) AS NEEDED TO ENSURE PROPER CLUTCH PACK THICKNESS.

14. MEASURE THICKNESS OF ONE TANG (14) ON EACH OF FOUR STEEL PLATES (11). IF STEEL

PLATE MEASURES 0.116-0.123 IN. (2.95-3.12 mm), STEEL PLATE IS THICK. IF STEEL PLATE

MEASURES 0.099-0.106 IN. (2.51-2.69 mm), STEEL PLATE IS THIN.

15. REPEAT STEPS 8 THRU 13 TO RECHECK CLUTCH PACK THICKNESS.

16. REMOVE CLUTCH PACK (12) FROM PRESS.

14-111