TM 9-2320-302-34

0041 00-8

PISTON AND CYLINDER ASSEMBLY MAINTENANCE - CONTINUED

0041 00

INSPECTION - CONTINUED

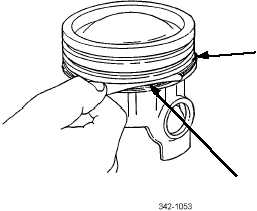

6.

Hold new oil control ring (16) in oil control ring groove so that oil control ring face is flush with edge of piston dome.

Do not push ring to bottom of oil control ring groove. Insert feeler gage (27) between top of oil control ring and ring

land of oil control ring groove in piston dome. If clearance is greater than 0.004 in (0.11 mm), discard dome.

CAUTION

In order to prevent possible damage to equipment, DO NOT use crocus cloth to polish or refinish piston pin.

Piston pins cannot be polished or refinished.

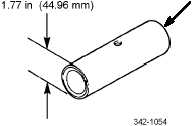

7.

If piston pin (11) shows signs of fretting, overheating or is worn to diameter of 1.77 in (44.96 mm), replace piston pin.

8.

Replace connecting rod (12) if subjected to any of the following:

a.

Visual damage (bent)

b.

Previous bearing or related failure

c.

Connecting rod bluing at top or bottom end

d.

Fretting at split line between connecting rod and connecting rod cap

e.

Excessive pound-in of rod bolt heads, nuts, and of piston pin bolt and spacer

f.

Unusual cylinder wear patterns

g.

Gouges, nicks or burrs on machined surface of connecting rods at piston pin end

16

27

11