TM 5-2330-325-13&P

0034

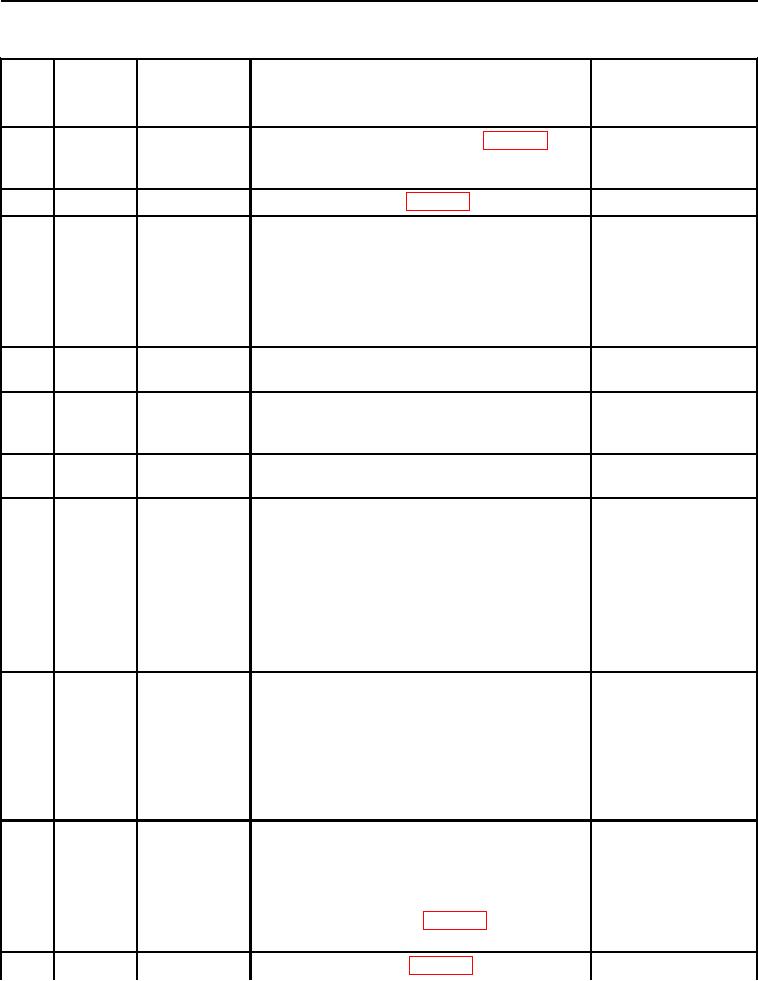

Table 1.

Field Preventive Maintenance Checks and Services (PMCS) - Continued.

ITEM TO BE

EQUIPMENT

ITEM

CHECKED OR

NOT READY/

NO.

INTERVAL

SERVICED

PROCEDURE

AVAILABLE IF:

4

Monthly

Electrical

Lubricate electrical connector hinges (WP 0093).

Connector

Hinges

5

Monthly

Slack Adjuster

Lubricate slack adjuster (WP 0093).

1. Measure tread depth. Measurements should be

6

Semiannual Wheels and

Tires

taken at random locations on tire.

2. To rotate and match tires. Refer to

TM-9-2610-200-14.

3. Check wheel nuts for tightness. Torque nuts to

450-500 lb ft (610-678 Nm).

7

Semiannual Brake Air

Check all air hoses for leaks, kinks, bends, cracks, and

System

missing mounting clamps.

8

Semiannual Brakes

Check for proper operation and adjustment.

Failure to operate

properly or are out

of adjustment.

9

Semiannual Brake Drums

Visually inspect brake drums for cracks, scoring,

Excessive wear, cracks,

gouging, or abnormal wear.

or damage.

10

Annual

Brake Linings

1. Check brake linings for sufficient material.

Brake shoes show

excessive wear (less than

0.0625 in. [1.59 mm]).

2. Check brake linings for damage.

Lining thickness less than

0.25 in. (6.4 mm) or to the

wear indicator if the lining

is so marked (measured

at the shoe center for

drum brakes).

11

Annual

Brake Drums

Measure brake drums to check for excessive wear.

Should not exceed 0.120

in. (3.04 mm) over the

original diameter. When

reboring brake drums, the

finished diameter should

not exceed .080 in. (2.03

mm) over the original

diameter.

12

Annual

Wheel Bearing

1. Remove wheel bearings and visually inspect for

Excessive wear or

and Seals

wear or damage.

damage.

2. Visually inspect bearing seal for wear or damage.

Excessive wear or

damage.

3. Lubricate wheel bearing (WP 0093).

Excessive leakage or

cracks in seal.

13

Annual

Lift Cylinder Pin

Lubricate lift cylinder pin (WP 0093).

0034-2

02/13/2013root(pmcswp)wpno(I1003)