TM 9-2320-363-34-2

CRANKSHAFT REPLACEMENT (CONT)

NOTE

If worn crankshaft maximum connecting rod bearing journal to bearing shell

clearance, with new shells, exceeds 0.005 In. (0.1270 mm), or if maximum main

bearing journal to bearing shell clearance, with new shells, exceeds 0.0056 in.

(0.1412 mm), replace crankshaft. Measurements of crankshaft should be accurate

to nearest 0.0001 in. (0.0025 mm). If main bearing journal taper of used

crankshaft exceeds 0.0015 in. (0.0381 mm), or if out-of-round clearance is

greater than 0.001 in. (0.0254 mm), replace crankshaft.

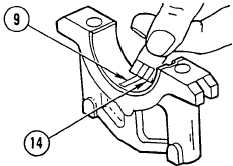

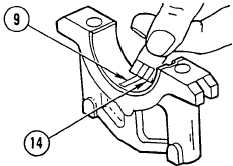

20. COMPARE WIDTH OF FLATTENED PLASTIGAUGE (9) AT WIDEST POINT WITH GRADUATIONS

ON ENVELOPE (14) AS SHOWN. NUMBER IN GRADUATION ON ENVELOPE (14) INDICATES

BEARING CLEARANCE IN THOUSANDTHS OF IN. MULTIPLY READING OBTAINED (IN

THOUSANDTHS) BY 25.4 TO OBTAIN METRIC SPECIFICATIONS. MEASURE EACH END OF

PLASTIGAUGE (9). DIFFERENCE BETWEEN TWO READINGS IS APPROXIMATE AMOUNT OF

TAPER.

NOTE

. Crankshaft failures are rare. When crankshaft cracks or breaks completely,

thoroughly inspect for contributory factors.

Unless abnormal conditions are

discovered and corrected, crankshaft failure will be repeated.

. When new or reground crankshaft is installed, all new main and connecting rod

(upper and lower) bearing shells and thrust washers must also be installed.

. If new crankshaft is to be installed, clean it to remove rust preventative and

blow out oil passages with compressed air.

. Replace vibration damper when installing new crankshaft.

CRANKSHAFT IS REPAIRABLE ONLY TO MANUFACTURER’S SPECIFICATIONS IF INSPECTION

CONDITIONS WARRANT. OTHERWISE, CRANKSHAFT REPLACEMENT IS REQUIRED.

12-52