TM 9-2320-363-34-2

CRANKSHAFT REPLACEMENT (CONT)

12.

13.

14.

- 15.

NOTE

Make sure all main bearing saddles and thrust bearing counterbores in cylinder

block are clean.

Each upper main bearing shell is grooved with oil hole. Register oil hole in

each upper main bearing shell with oil hole in each main bearing saddle of

cylinder block.

Install main bearings in sets only. Do not mix old and new main bearing shells

on same journal. If old bearings are installed, they must be installed in same

journal they were removed from.

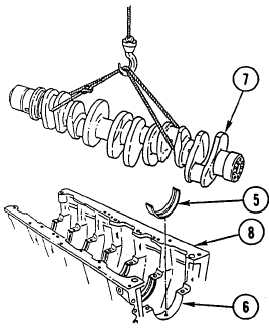

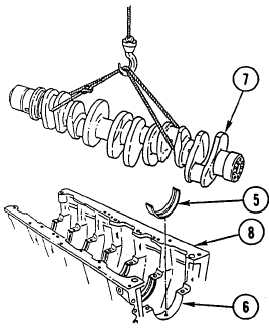

INVERT ENGINE BLOCK. INSTALL SEVEN UPPER MAIN BEARING SHELLS (5) IN CYLINDER

BLOCK JOURNALS (6).

WIPE OIL FROM BEARING SHELLS AND CRANKSHAFT JOURNALS TO BE CHECKED.

WARNING

Crankshaft weighs 408 lb (185.23 kg). Use suitable lifting device to lift and

support crankshaft. Failure to do so could result in serious injury to personnel.

USING NYLON ROPE AND SUITABLE LIFTING DEVICE, POSITION CRANKSHAFT (7) IN CYLINDER

BLOCK (8) ON UPPER MAIN BEARING SHELLS (5).

USING STRIP OF PLASTIGAUGE. MEASURE BEARING CLEARANCES BETWEEN Crankshaft

JOURNALS OF MAIN BEARINGS. PLASTIGAUGE TYPE PG-1 (GREEN) HAS CLEARANCE RANGE

OF 0.001-0.003 IN. (0.0254-0.0762 mm). TYPE PR-21 (RED) HAS CLEARANCE RANGE OF

0.002-0.006 IN. (0.0508-0.01524 mm). TYPE PB-I (BLUE) HAS CLEARANCE OF 0.004-0.009 IN.

(0.1016-0.2286 mm).

12-50