TM 5-2330-361-14&P

adiuster rotates the camshaft, which forces the brake

4-16.

A i r hoses should be checked for chafing,

shoes against the brake drum.

bends, andkinking every month/2000 miles. Replace

faulty hoses.

424. OPERATING CHECKS.

4 - 2 5 . During road stops, take time to check the

4 - 1 7 . AIR BRAKE CHAMBERS.

brake drums for a heating condition. Proceed cau-

tiously since malfunctioning or misadjusted brakes

4-18. The air system tests in paragraph 4-12 should

can case the drum to become extremely hot. Valve

disclose any malfunctioning brake chambers. Repair

stems may be burned by the hot drum. Do not at-

or replace faulty units.

Every 2,000 miles check the

tempt to operate the vehicle until the problem caus-

c o n d e n s a t i o n holes on the underside of the brake

ing the overheating is corrected. A cool brake drum

chambers to make sure they are open.

The brake

may indicate an inoperative brake. Test is outlined

c h a m b e r s should be disassembled and cleaned at

in paragraph 4-12.

50,000 miles or yearly.

The diaphragm and any mar-

ginal parts should be replaced. When replacing the

4 - 2 6 . BRAKE ASSEMBLY.

diaphragm or spring, replace the corresponding ports

4-27.

The

brake

assemblies

should

be

for the other chamber on the same axle (to aid in

in~spected

every

2000

miles

or

monthly.

even brake application and release). Examine yoke

Remove the dust shields and examine the

pin for wear and replace if necessary.

brake linings visua 1 ly to locate the

lining showing the greatest amount of

4 - 1 9 . RELAY EMERGENCY VALVE.

wear.

The wheel and drum should be re-

moved and the lining replaced

if

the

4 - 2 0 . The air system tests in paragraph 4-12 may

thinnest portion of the lining

is

3/8

disclose a malfunction of the reloy emergency valve.

in.

(9.5

mm)

or

less.

Do

not

allow

the

Repair or replace faulty units. The relay Valve

linings to wear thin enough so the lin-

s h o u l d be disassembled and cleaned every 50,000

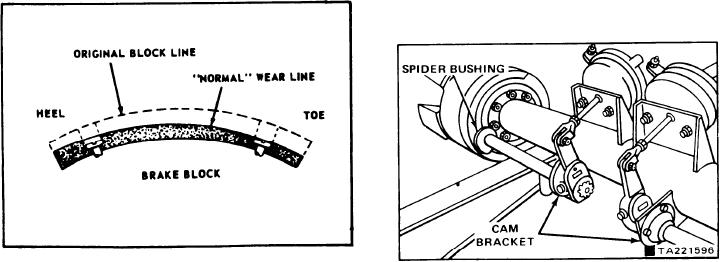

ing rivet contacts the drum (see Figure

R e p l a c e worn parts. Contact an

miles or yearly.

4-3).

authorized representative of the original equipment

4-28.

manufacturer for relay valve servicing.

Grease the camshaft

bracket bear-

ing and the spider bushing

at 4 locations

per

axle

every

25,000

miles

(see

Figure

4-21.

AIR

BRAKES.

4-4).

Remove

dust

shields

to

grease

cam

DO NOT use an ex-

shaft

spider

bushing.

4-22.

GENERAL.

cessive amount of grease on the anchor

pins and spider bushing to avoid getting

4 - 2 3 . HYSTER trailers are equipped with cam ac-

grease

on

brake

lining

surfaces.

tuated brakes.

B r a k i n g force is supplied by air

pressure in the brake chamber, which pushes a push-

4-29. SLACK ADJUSTER.

rod against the end of the slack adjuster. The slack

4-30.

Automatic

slack

adjusters compen-

Inspect and

sate for brake lining

wear.

grease slack adjusters

every

25,000

miles

or

yearly.

FIGURE 4-3. BRAKE BLOCK WEAR.

FIGURE 4-4. GREASE ZERK LOCATIONS

ON AXLE.

Change 3 4-4