TM 9-2320-363-34-2

CAUTION

Use press plate, P/N 51100, or support equalizing beam bore square on press

bed. Failure to do so could result in bent beam, requiring replacement

1.

2.

3.

3.1.

3.2.

4.

REMOVE GREASE FITTING (6) FROM EQUALIZING BEAM (2).

NOTE

Procedure is the same for all vehicles except as noted.

M915A2 Only: Removal of bushings requires 50-ton or larger press

M916A1 Only: Removal of bushings requires 100-ton or larger press

USING SUITABLE PRESS, REMOVING ADAPTER P/N 302030, PRESS ADAPTER PIN 206457,

REMOVE AND DISCARD TWO END BUSHINGS (I) FROM EQUALIZING BEAM (2)

NOTE

Perform step 2 on M915A2 only.

USING SUITABLE PRESS, REMOVING ADAPTER P/N 302027, AND PRESS ADAPTER P/N 206457

REMOVE AND DISCARD CENTER BUSHING (3) FROM EQUALIZING BEAM (2)

NOTE

Perform step 3 on M916A1 only

USING SUITABLE PRESS AND REMOVING ADAPTER P/N 38095. REMOVE AND DISCARD TWO

SEALS (4) AND CENTER BUSHING ASSEMBLY (5).

NOTE

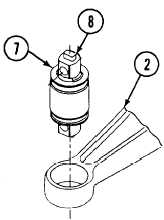

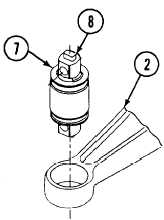

Perform steps 3.1 and 3.2 on

M916A2, M917A1, and M917A1

w/MCS only.

USING CHISEL AND HAMMER, CUT AND

REMOVE BUSHING RETAINING WASHER

(7). REMOVE ANY PROTRUDING RUBBER

TO PREVENT INTERFERENCE WHILE

PRESSING BAR PIN BUSHING OUT.

USING SUITABLE PRESS AND PIN

ADAPTER SET P/N 1747, REMOVE AND

DISCARD TWO BAR PIN BUSHINGS (8)

FROM EQUALIZING BEAM (2).

NOTE

Perform step 4 on all except M915A2 only.

Change 1 21-3