TM 9-2320-363-34-2

PISTON AND CYLINDER ASSEMBLY REPLACEMENT (CONT)

46.

NOTE

Perform step 46 only if performing plastigauge check.

Go to step 47 if not performing plastigauge check.

CHECK CLEARANCE BETWEEN CONNECTING ROD BEARING SHELLS

JOURNAL AT TIME OF CONNECTING ROD AND PISTON ASSEMBLY

FOLLOWS:

A.

B.

C.

D.

E.

F.

G.

H.

AND CRANKSHAFT

INSTALLATION AS

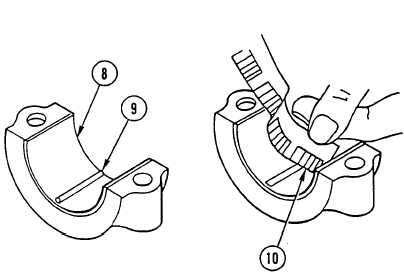

WITH UPPER AND LOWER BEARING SHELLS (8) INSTALLED IN CONNECTING ROD AND

CONNECTING ROD CAP, WIPE ANY OIL FROM BEARING SHELLS (8) AND CONNECTING

ROD JOURNAL.

PLACE PIECE OF PLASTIGAUGE (9) ALONG FULL WIDTH OF LOWER CONNECTING ROD

BEARING SHELL (8) ABOUT 1/4 IN. (6.35 mm) OFF CENTER.

INSTALL CONNECTING ROD AND ROD BOLTS ON CRANKSHAFT BEARING JOURNAL IN

ITS CORRESPONDING CYLINDER.

INSTALL CONNECTING ROD CAP AND CAP NUTS ON CONNECTING ROD AND TIGHTEN

CONNECTING ROD CAP NUTS TO 118-137 LB-FT (160-185 N.m.).

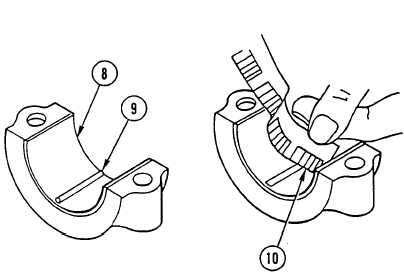

REMOVE CONNECTING ROD CAP AND BEARING SHELL (8).

FLATTENED PLASTIGAUGE (9) WILL ADHERE TO EITHER BEARING SHELL OR

CONNECTING ROD JOURNAL. COMPARE WIDTH OF PLASTIGAUGE (9) AT WIDEST POINT

WITH GRADUATIONS SCALE (10) ON PLASTIGAUGE (9) ENVELOPE TO DETERMINE

CONNECTING ROD BEARING CLEARANCE. MAXIMUM CONNECTING ROD BEARING TO

CONNECTING ROD JOURNAL CLEARANCE WITH USED PARTS IS 0.006 IN. (0.152 mm).

INSPECT CRANKSHAFT JOURNALS BEFORE INSTALLING BEARINGS (PAGE 12-41).

COAT CONNECTING ROD BEARING

LUBRICATING OIL BEFORE ASSEMBLY.

SHELLS AND JOURNAL WITH CLEAN ENGINE

12-168