TM 9-2320-363-34-1

Table 3-1. Troubleshooting (Cont)

Malfunction

Test or lnspection

Corrective Action

HYDRAULIC WINCH (M916A1 AND M916A2) (CONT)

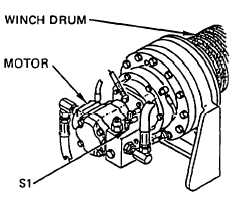

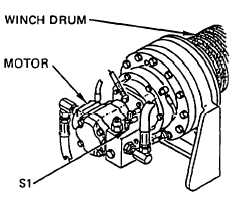

Step 2. Check for insufficient system pressure to brake. Check hydraulic system

pressure. Install pressure gage with capacity of 3000 psi (20685 kPa) in

brake pilot line and plug port S1 in counterbalance manifold. Apply hydraulic

power, run engine at 1000 rpm, and observe pressure on gage.

l If pressure is below 270 psi (1861 kPa), repair (page 23-12) or

replace hydraulic pump (page 11-2).

l If pressure is at least 270 psi (1861 kPa), check for jammed

gearing in winch, or repair brake (pages 23-2, 23-26, 23-34).

6. BRAKE WILL NOT APPLY. OR APPLIES BUT TORQUE LOW.

Check for damaged springs or friction plates.

l Repair (page 23-9) or replace hydraulic motor (page 11-15).

ARCTIC HEATER

1. HEATER WILL NOT START, BLOWER DOES NOT RUN.

Step 1. Check for damaged wiring.

l Repair (page 25-34) or replace wiring (page 25-34).

Step 2. Check for defective blower motor.

l Replace blower motor (page 25-26).

2. BLOWER RUNS WHEN SWITCH IS IN START POSITION, BUT HEATER WILL NOT IGNITE.

Step 1. Check for defective flame detector switch.

l Replace flame detector switch (page 25-30).

2-26

Change 1