TM 9-2320-363-10

3-10. FRONT WHEEL AND TIRE ASSEMBLY REPLACEMENT

(M917A1 AND M917A1 W/MCS) (Con’t).

(5)

Remove protective plug from wheel valve (8) and install on

wheel valve of defective tire.

(6)

Connect connector (7) to wheel valve (8).

NOTE

Ensure hose is not kinked after connecting to elbow.

Rotate elbow, if necessary.

(7)

Connect hose (6) to elbow (5).

NOTE

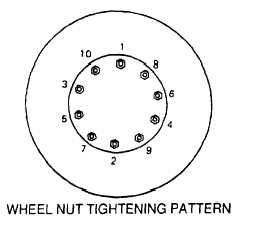

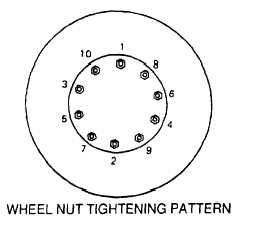

Tighten wheel nuts with wheel wrench. After 25

miles (40 km), retighten wheel nuts. Within next 75

miles (121 km), have Unit Maintenance torque wheel

nuts to proper torque.

Tightening pattern is identical for ail wheel assem-

blies.

(8)

Tighten

wheel

nuts according to wheel tightening pat-

tern.

(9)

Stow defective tire in spare wheel and tire carrier (paragraph

3-8) and have it replaced or repaired as soon as possible.

(10)

Notify Unit Maintenance as soon as possible to apply proper

torque.

(11)

Inflate tire to desired pressure using CTIS (paragraph 2-17)

or manual inflation procedure (paragraph 3-7).

(12)

Remove wheel blocks.

3-31