TM 5-2330-325-14&P

3-8.

TIRE ASSEMBLY REPLACEMENT (Continued).

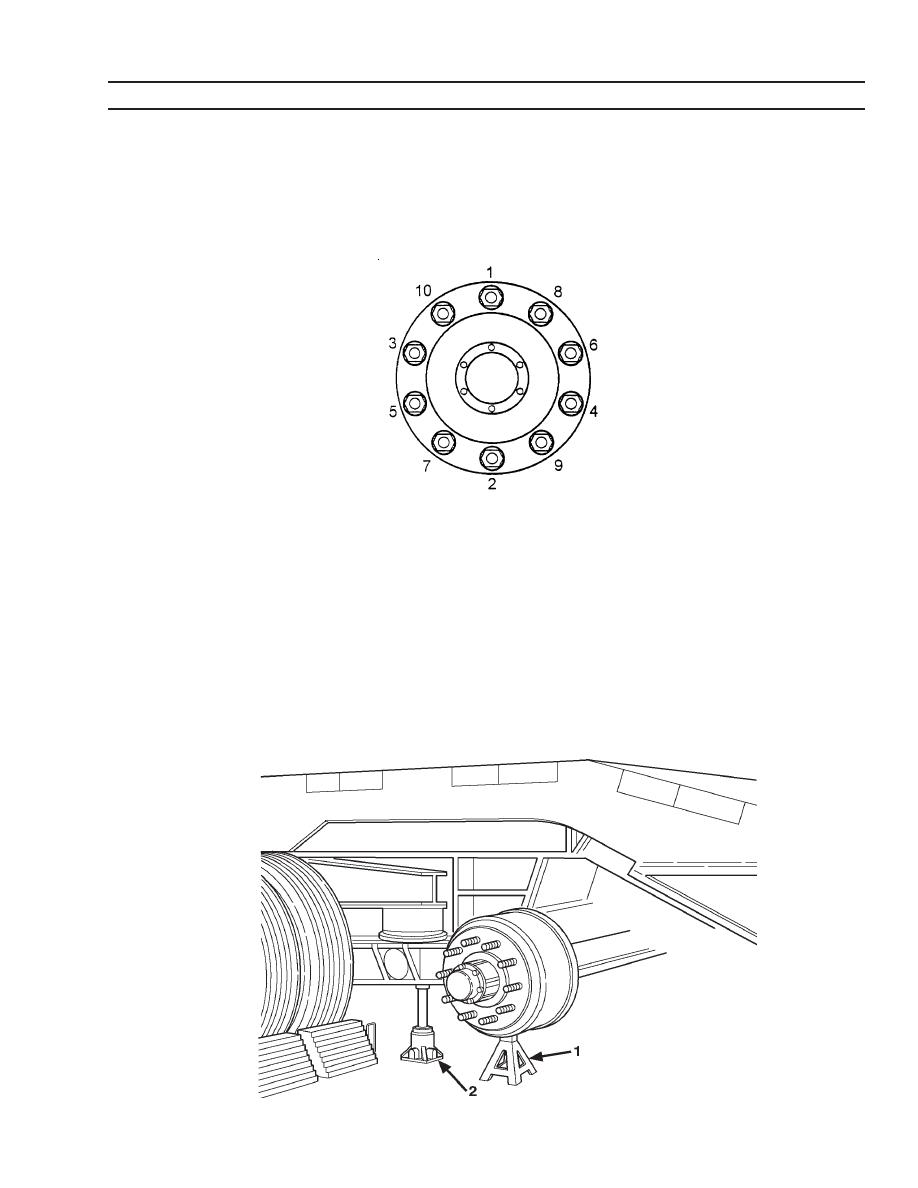

As soon as possible, have Unit Maintenance torque lug nuts to 450-500 ft-lb (610.2 Nm to

(5)

678 Nm) in accordance with lug nut tightening sequence illustrated below.

(6)

Using gage and hose assembly, check tire assembly for proper air pressure. Adjust air

pressure as required. Trailer air supply may be used by attaching air hose to connector

located next to air reservoir dump valve.

Tightening Sequence for Lug Nuts

(7)

Check alignment of tire assembly. Place a block of wood or other object on the ground at

the side of the tire and rotate the wheel. If the distance between the block of wood and the

tire varies by more than 1/8 in. (.32 cm), the tire assembly is not properly mounted. To

correct, loosen the nut on the side with the greatest deviation and tighten the nuts on the

opposite side. Recheck the torque and the alignment.

NOTE

Lug nuts should be rechecked for proper tightness after the first 50 miles

(80.5 Km) to 100 miles (160.9 Km) of operation after wheel reinstallation.

(8)

Remove jack stands (1), lower axle, and remove hydraulic jack (2).

3-13