TM 9-2320-363-34-2

CAB BODY REPAIR (CONT)

2.

REQUIRED RIVET SPACING IS DETERMINED BY STRENGTH NEEDED IN JOINT. GENERAL FEEL

FOR STRENGTH REQUIRED CAN BE OBTAINED BY INSPECTING RIVET PATTERNS IN

SURROUNDING AREAS. BODY REPAIRS MADE USING SINGLE ROWS OF RIVETS SHOULD BE

PERFORMED USING RIVET SPACING NOT GREATER THAN 1-1/2 IN. (4 cm), AND NOT LESS

THAN 5/8 IN. (16 mm). USE 1 IN. RIVET SPACING AS GENERAL PRACTICE FOR REPAIRS. RIVET

SPACING USED IN ORIGINAL CONSTRUCTION MAY BE GREATER DUE TO ADDITIONAL

STRENGTH OBTAINED BY USING FOAM ADHESIVE TAPE. DO NOT USE RIVET EDGE

DISTANCES LESS THAN 3/8 IN. (5 mm).

3.

HIGH-STRENGTH JOINTS OR LARGE AREA PATCHES MAY REQUIRE USE OF DOUBLE OR

MULTIPLE ROWS OF RIVETS TO OBTAIN SUFFICIENT STRENGTH.

C A U T I O N

Be careful not to distort original holes to prevent damage to equipment.

4.

CARE MUST BE TAKEN TO ASSURE RIVET HOLE PATTERNS ARE TRANSFERRED ACCURATELY

IN CASE WHERE PART WITH NO HOLES IS MATED TO ONE WHICH ALREADY HAS RIVET

HOLES. HOLE PATTERNS MAY BE TRANSFERRED USING ONE OF FOLLOWING:

LAY NEW PART IN PLACE AND USE HOLES IN MATING PART AS DRILL TEMPLATE. NEW

PART MUST BE UNDERNEATH MATING PART.

USE REMOVED PART AS DRILL TEMPLATE BY CLAMPING OLD AND NEW PARTS

TOGETHER. PARTS MUST NEST FLAT AND RIVET FLANGE MUST BE UNDISTORTED.

Joint Design

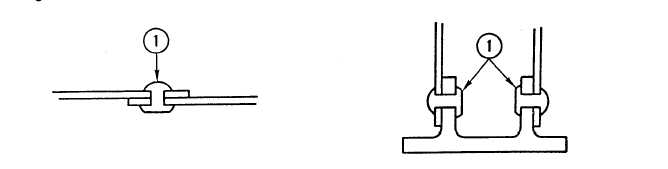

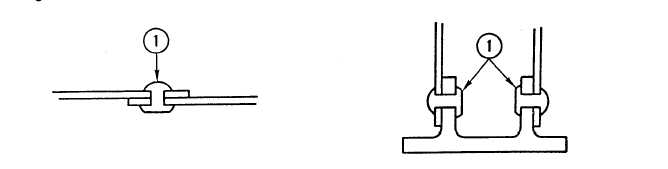

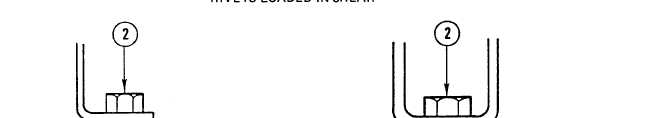

RIVETS LOADED IN SHEAR

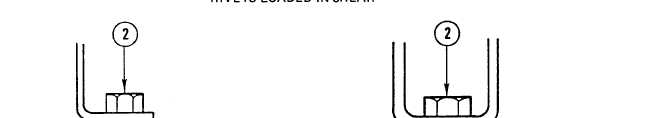

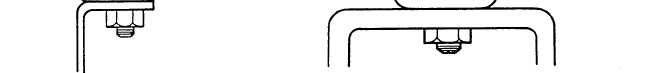

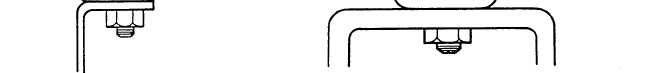

BOLTS REPLACING RIVETS LOADED IN TENSION

22-24