TM 9-2320-363-34-2

CAB BODY REPAIR (CONT)

Hole Countersinking

NOTE

Some rivet installations in body require that rivet head be flush with material

surface. In these instances, countersunk or flush head rivets are used.

1.

WHEN USING COUNTERSUNK RIVETS, RIVET HOLES MUST BE COUNTERSUNK WITH TOOL

HAVING 100-DEGREE TAPER SO RIVET HEAD WILL FIT FLUSH WITH SURFACE.

2.

WHEN USING HAND-OPERATED COUNTERSINK, HOLE MUST BE TRIED WITH RIVET SO

RECESS WILL NOT BE TOO DEEP OR TOO SHALLOW. IT IS BEST TO USE COUNTERSINK WITH

STOP SO DEPTH OF COUNTERSINK CAN BE CONTROLLED, TYPICAL COUNTERSINKING

DIMENSIONS FOR BLIND RIVETS ARE SHOWN IN TABLE 3. MINIMUM SHEET THICKNESS THAT

CAN BE MACHINED FOR 100-DEGREE COUNTERSINK RIVETS IS GIVEN IN TABLE 4.

3.

DO NOT REMOVE EDGE OF HOLE ON BLIND SIDE OF JOINT.

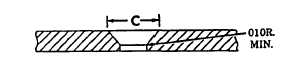

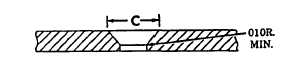

Table 3. Countersinking Dimensions for

100-Degree Countersunk Blind Rivets

Countersinking Dimensions (100°)

Rivet

C (In.)

Diameter

(In.)

Minimum

Maximum

I

1/8

I

0.222

I

0.228

5/32

0.283

0.289

3/16

0.350

0.356

Table 4. Minimum Sheet Gage for 100-Degree Machine Countersink

Rivet Size (In.)

3/32

1/8

5/32

3/16

1/4

I Gage (In.)

I 0.040

0.050

0.064

0.072

0.072 I

22-18