TM 9-2320-363-34-2

46.

CLEAN VALVE SEAT THOROUGHLY. CHECK SEAT-TO-VALVE FACE CONTACT BY APPLYING

LIGHT COAT OF PRUSSIAN BLUE PASTE TOVALVE SEAT LAND. INSERT VALVE IN GUIDE AND

BOUNCE HEAD ON SEAT INSERT WITHOUT ROTATING VALVE. FULL 360-DEGREE CONTACT

LINE SHOULD APPEAR CENTERED ON VALVE FACE.

NOTE

Reduced-thickness valve seat inserts are available 0.010, 0.020, and 0.030 in.

(0.254, 0.508, and 0.762 mm) shallower than standard. When reduced-thickness

inserts are used, install correspondingly thicker valve spring seats.

VALVE HEAD RECESS DEPTH FROM CYLINDER HEAD FIRE DECK IS INCREASED BY GRINDING

VALVE SEAT. CHECK WITH SLED GAGE (42). REPLACE VALVE SEAT IF NOT BETWEEN

0.055-0.067 IN. (1.4-1.6 mm).

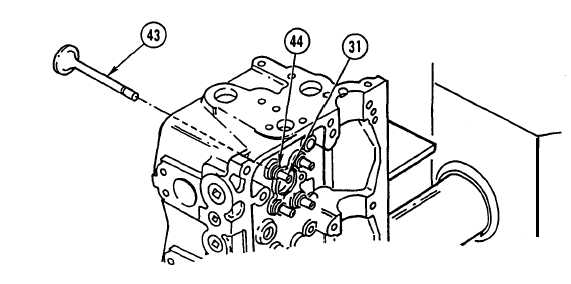

47.

46.

POSITION CYLINDER HEAD STEP.

NOTE

Intake valves have larger faces and are installed in guides on cam side of

cylinder head. Smaller exhaust valves are installed in guides on thermostat side

of cylinder head.

LUBRICATE VALVE STEM (43) WITH CLEAN ENGINE LUBRICATING OIL AND INSERT VALVE

INTO VALVE GUIDE (31) FROM FIRE DECK SIDE OF CYLINDER HEAD.

49.

I

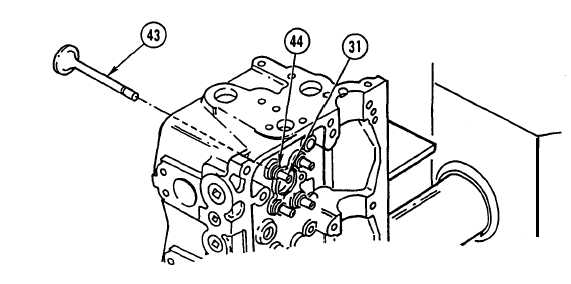

C A U T I O N

I

If other than standard valve seat has been installed, use correspondingly

thicker valve spring seat. Failure to do so could result in damage to

equipment.

INSTALL VALVE SPRING SEAT (44) OVERVALVE GUIDE (31) AND AGAINST TOP OF CYLINDER

HEAD.

12-37