TM 9-2320-302-34

0032 00-10

CYLINDER HEAD REPAIR - CONTINUED

0032 00

CLEANING AND INSPECTION - CONTINUED

NOTE

•

Leaking injector tubes must be replaced. Replace any pipe plug or cup plug where leakage is present.

•

Cylinder head must be pressure tested following replacement of any injector tubes, cup plugs or pipe

plugs.

3.

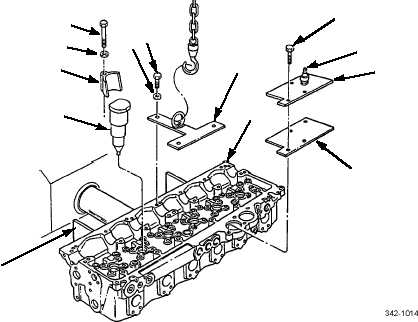

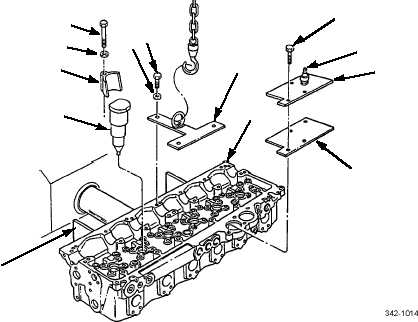

Install gasket (33) and pressure test kit thermostat cover plate (34) on cylinder head (2) with bolts (35).

4.

Using hardware provided, install material lift clamp (1).

5.

Install pressure test kit dummy fuel injectors (36) in injector bores.

6.

Install fuel injector hold down clamp (37), washer (38), and hold down bolt (39). Tighten bolt to 43-49 lb-ft (58-66 Nm).

7.

Remove cylinder head (2) from engine mounting bracket (5).

WARNING

Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never exceed 30 psi

(207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to avoid injury to person-

nel.

8.

Apply 30 psi (207 kPa) air pressure to thermostat cover plate fitting (40).

9.

Install pipe plugs in temp port and in air compressor coolant port.

10.

Immerse cylinder head (2) in water heated to 180°F-200°F (82°C-93°C). Leave cylinder head in water for 20 minutes.

Watch for bubbles, indicating crack or leak. If cracked, replace cylinder head.

11.

Using heavy straightedge (41) and thickness gage (42), check for warped cylinder head fire deck (20).

36

5

37

38

39

11

1

2

35

40

34

33