TM 5-2330-325-14&P

5-11.

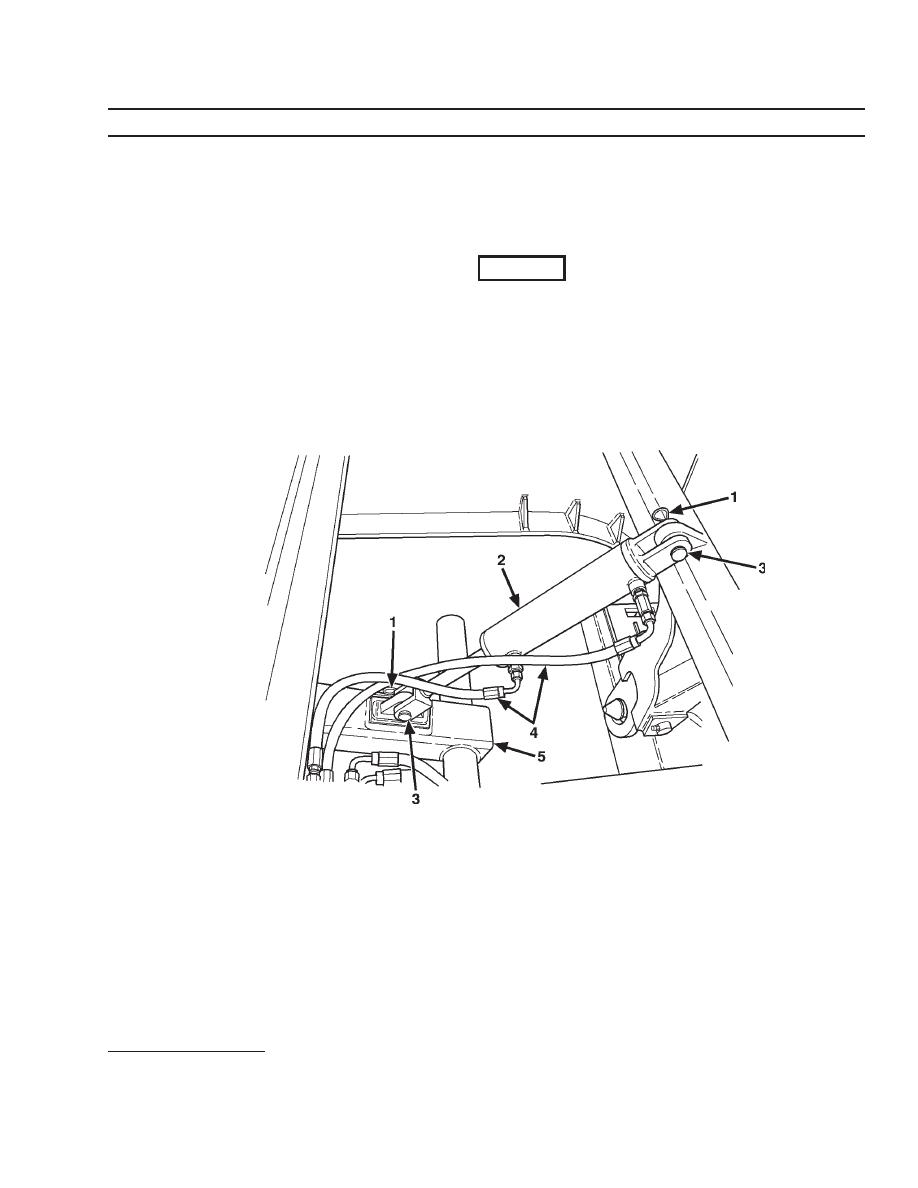

TILT CYLINDER REPLACEMENT (Continued).

(1)

Release all pressure from hydraulic lines by disconnecting gooseneck hydraulics from

power source.

(2)

Tag and disconnect two hydraulic lines (4) from tilt cylinder (2) and cap or seal lines.

CAUTION

Cap or plug all ports and hose ends to prevent contamination of hydraulic

oil. Failure to do so may result in damage to equipment.

(3)

Support gooseneck tilt arm (5).

(4)

Remove upper and lower cotter pins (1) from tilt arm and withdraw cylinder attaching pins

(3).

(5)

Remove tilt cylinder (2)

b.

Installation.

(1)

Install tilt cylinder (2) between gooseneck frame and tilt arm (5) and secure upper and lower

ends with cylinder attaching pins (3).

(2)

Lock cylinder attaching pins (3) in place by inserting cotter pins (1) and bend pins to

secure.

(3)

Remove caps or sealing tape from ends of hydraulic lines and apply anti-seize tape to

threads of inlet and outlet ports of tilt cylinder (2).

(4)

Connect hydraulic lines (4) to tilt cylinder (2) and apply hydraulic pressure to test operation

and check for leaks.

(5)

Extend and retract tilt cylinder (2) ten times to remove air from system.

FOLLOW-ON TASKS:

None.

5-25