TM 9-2320-302-34

0032 00-20

CYLINDER HEAD REPAIR - CONTINUED

0032 00

ASSEMBLY - CONTINUED

CAUTION

Be careful not to drop reconditioning set seat reamer into pilot or allow seat reamer to strike injector tube.

Sharp cutting edges may gouge injector tube causing chatter marks in seat.

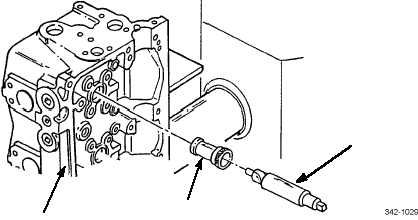

24.

Install injector tube reconditioning set seat reamer pilot (66) in injector tube bore until it contacts cylinder head (2).

CAUTION

When using seat reamer, use only light pressure. Heavier pressure will result in chatter marks in seat.

25.

Apply a few drops of cutting oil on edges of injector tube reconditioning set seat reamer (70) and place gently in pilot

(66).

26.

Using speed handle with 12-point (23-mm) socket, turn injector tube reconditioning set seat reamer (70) in clockwise

direction. Use light pressure until reamer bottoms against injector tube reconditioning set stop block (69).

WARNING

Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never exceed 30 psi

(207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to avoid injury to person-

nel.

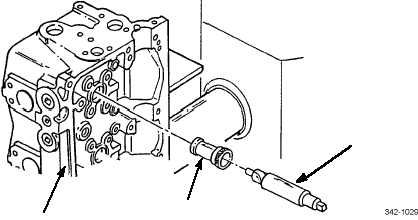

27.

Remove reamer and pilot. Using compressed air, clean out injector tube.

28.

Inspect tube seating surface for irregularities or chatter marks (71) in seating surface. If irregularities or chatter marks

are present, remove and replace injector tube.

66

70

2