Mark lines.

10-21.2. STEERING STOP INSPECTION AND ADJUSTMENT PROCEDURES (Continued).

LOCATION/lTEM

ACTION

REMARKS

NOTE

Check that alignment marks on the pitman arm steering gear sector shaft

are in alignment before performing the steering stop adjustment proce-

dure.

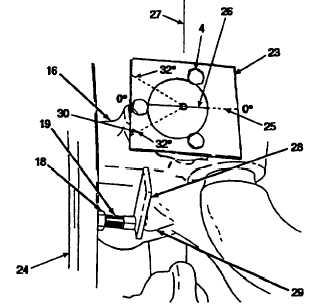

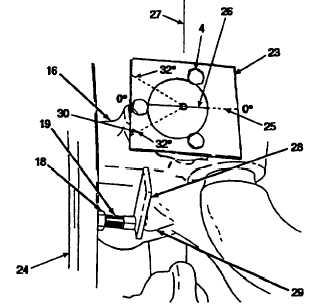

1. Template (23), steering knuckle housing (16),

Install.

Put template on top of

and three cover bolts (4).

housing, and partially in-

stall bolts to position tem-

plate.

2. Front brake drums (24).

Center and

Make two measurements,

measure.

the first at the forward side

of the brake drum, meas-

uring the distance “d” from

the frame to the back of

the brake drum. Then

make the same measure-

ment at the rear of the

brake drum. Adjust as

necessary to make the

measurements equal.

3. Template (23).

Put straight edge on zero

degree reference line (25)

and mark a line (26)

across the king pin. Line

(26) should be perpendicu-

lar to the line of travel (27).

NOTE

A 1/8-inch spacer must be used when adjusting the steering stops in order

to acquire the correct steer angle.

4. 1/8-inch spacer (28), steering stop bolt (19),

Position, adjust,

Put spacer between

steering stop boss (29), brake drum (24),

and tighten.

steering stop bolt and

king pin line (26), 32 degree reference

steering stop boss, turn

line (30), template (23), and jam nut (18).

brake drum full left

until king pin line aligns

with 32 degree reference

line on template. If the 32

degree reference line

does not line up with the

king pin line, adjust steer-

ing stop bolt. Tighten jam

nut and remove spacer.

Change 3 10-84.9

STEERING MECHANISM.

TM 9-2320-273-20