TM 9-2320-363-34-1

Table 2-1. Troubleshooting (Cont)

Malfunction

Test or lnspection

Corrective Action

TRANSMISSION (CONT)

2. TRANSMISSION NOISY.

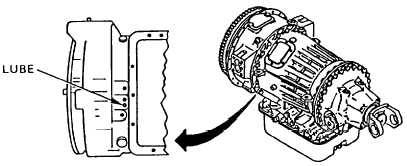

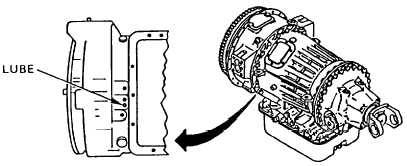

Step 1. Check for low lubrication oil pressure. Remove plug from lube port. Install

0 to 100 psi (0 to 690 kPa) gage. Start engine and allow to run at idle

speed. With parking brake applied, shift transmission into DRIVE and

accelerate engine to approximately 1900 rpm. Check for 25 to 30 psi

(172 to 207 kPa) lube system pressure.

If pressure is less than 25 or more than 30 psi (172 to

207 kPa), disassemble transmission (page 14-1) and check

torque converter, planetary gear assemblies, and bearings for

damage.

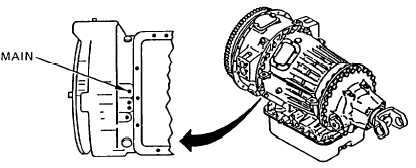

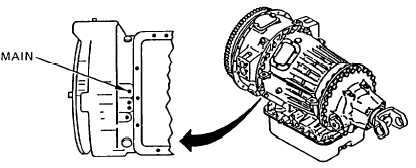

Step 2.

Check for low main pressure. Remove oil line (all except M915A2) or plug

(M915A2) from main pressure port on transmission and install tee (all except

M915A2) and 0 to 300 psi (0 to 2070 kPa) gage. Start engine and allow to

run at idle speed (600 rpm). With parking brake applied, shift transmission

into DRIVE. Check for 80 to 100 psi (552 to 690 kPa) main system pressure.

l If pressure is less than 80 or more than 100 psi (552 to

690 kPa), disassemble transmission (page 14-27) and inspect

lubrication pressure regulator and converter bypass valve for

damage. Inspect all other moving parts for damage from lack

of oil.

Change 1 2-9