TM 9-2320-302-20

0021 00-16

Table 1. Unit Preventive Maintenance Checks and Services (PMCS)

for the M915A3 Tractor Truck - Continued.

ITEM

NO.

INTERVAL

LOCATION

PROCEDURE

NOT FULLY MISSION

CAPABLE IF:

ITEM TO

CHECK/

SERVICE

30

Semi-

annual

Drivelines

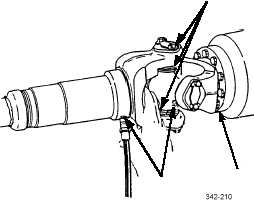

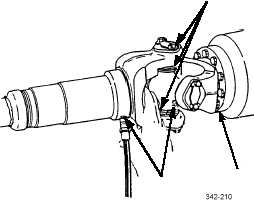

a. Check for looseness or side play in front

and rear drivelines. There should be no

play at U-joints. Check for bends, cracks,

and missing weights. Make repairs as

needed.

b. Check that U-joint mounting screw torque

is 33-38 lb-ft (44-52 Nm).

c. Inspect for loose or worn bearings, dam-

aged seals, and damaged or missing grease

fittings. Make repairs as needed.

d. Using a hand-type grease gun, lubricate

five grease fittings (22) at each driveline

with grease (Item 15, WP 0235 00) until

purging takes place at air hole in end of

slip yoke. Cover pressure relief hole while

lubricating.

e. Inspect for damaged or leaking input or

output shaft seals (23). If damaged or leak-

ing, notify Direct Support Maintenance.

31

Semi-

annual

Rear Axles,

Suspension

a. Inspect spring pack for cracks or breaks.

b. Inspect spring pack and attaching hard-

ware for looseness, cracks, or other dam-

age. Tighten or replace damaged compon-

ents, if authorized.

22

23

22