TM 9-2320-302-20

0021 00-5

Table 1. Unit Preventive Maintenance Checks and Services (PMCS)

for the M915A3 Tractor Truck - Continued.

ITEM

NO.

INTERVAL

LOCATION

PROCEDURE

NOT FULLY MISSION

CAPABLE IF:

ITEM TO

CHECK/

SERVICE

9

(Con’t)

Semi-

annual

Engine

Compartment,

Engine

d. Check mounting hardware and attaching

hardware for looseness. Tighten or replace

any damaged component, if authorized.

WARNING

DO NOT perform fuel system checks, inspections or maintenance while

smoking or near fire, flame or sparks. Fuel may ignite, causing injury or

death to personnel and damage to vehicle.

10

Semi-

annual

Engine

Compartment,

Fuel System

a. Replace all fuel filter elements.

b. Inspect fuel lines, fuel tank, and fuel sys-

tem components for leaks and damage. If

authorized, replace damaged components.

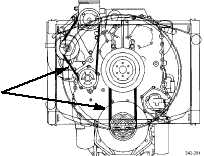

11

Semi-

annual

Engine

Compartment,

Drive Belts and

Pulleys

a. Check for loose, missing, worn, broken,

frayed or cracked drive belts (5).

b. Check alternator and air conditioning

compressor

mounting

for

looseness.

Inspect brackets and attaching hardware

for cracks, bends, and loose mounting.

Replace damaged components as needed.

c. Use a dial indicating tensionmeter (Item

32, WP 0236 00) placed at the center of

the longest belt free-span to check belt

tension. Gage should register 80-100 lb-ft

(108-135 Nm) for alternator and AC com-

pressor belt. Gage should register 60-80

lb-ft (81-108 Nm) for fan belt. Adjust ten-

sion as required.

5