W T E C I I I E L E C T R O N I C C O N T R O L S T R O U B L E S H O O T I N G M A N U A L

0011 00–123

APPENDIX B — CHECKING CLUTCH AND RETARDER PRESSURES

Checking individual clutch pressures helps to determine if a transmission malfunction is due to a mechanical or an

electrical problem. Properly making these pressure checks requires transmission and vehicle (or test stand)

preparation, recording of data, and comparing recorded data against specifications provided. These instructions are

for all WT Series transmissions.

NOTE:

Check to see if there are diagnostic codes set which are related to the transmission difficulty you are

evaluating. Proceed to make mechanical preparations for checking clutch pressures after codes have

first been evaluated.

A.

Transmission and Vehicle Preparation

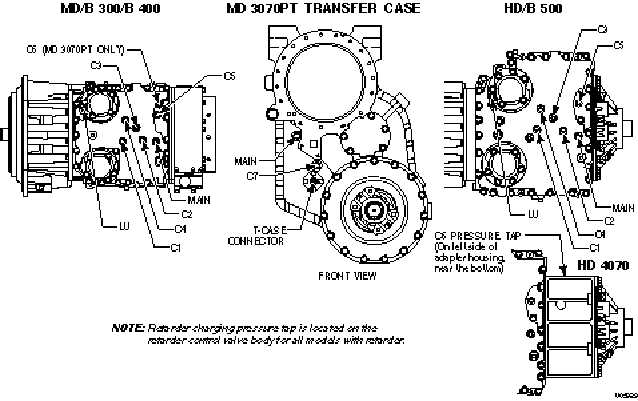

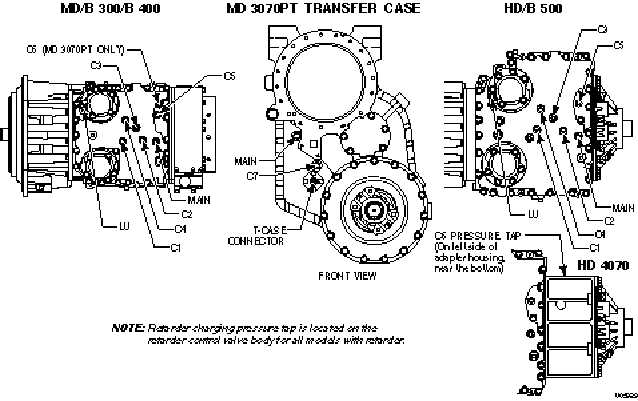

1. Remove the plugs from the pressure tap locations where measurement is desired (refer to

Figure B–1).

Figure B–1. Clutch Pressure Check Points

2. Install hydraulic fittings suitable for attaching pressure gauges or transducers.

3. Connect pressure gauges or transducers. Pressure gauge set J26417-A is available for this

purpose. See Table B–2 for pressure levels expected.

4. Check that engine speed can be monitored (Pro-Link® 9000 diagnostic tool may be used for this

purpose).

CAUTION:

Be sure that the hydraulic fittings have the same thread as the plugs removed

(7/16-20 UNF-2A). Also please note that these fittings must be straight thread,

O-ring style. Failure to do this will result in damage to the control module.